Machine Design Solutions for Automation Equipment

Our 3D automation machine design services improve efficiency, reduce errors, and provide a smart design package.

A full range of engineering specialties

Automation Equipment Machine Design Solutions & Services

Whether your process requires complex multi-station assembly lines, dial index machines, robotic cells, single station machines, or just a simple fixture, Cardinal Machine Company can meet your requirements.

Our engineering team has the knowledge and experience necessary to ensure the success of your project. Our automation machine design solutions include a full array of services.

We have a complete in-house staff of 3D designers skilled at:

- Mechanical engineering

- Electrical Engineering

- Fluid Power

- Controls

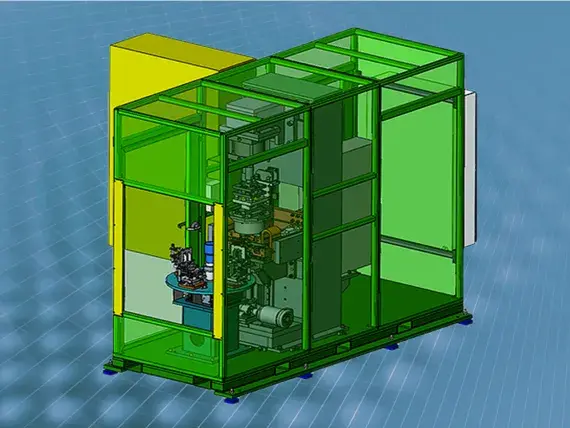

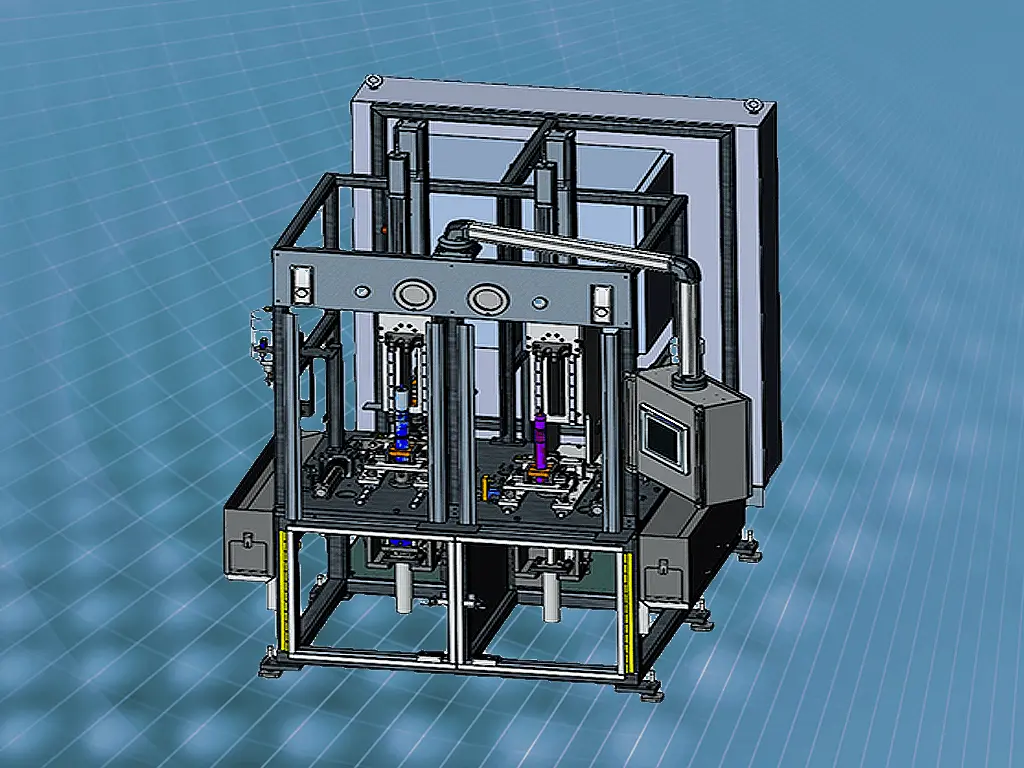

high-tech 3d machine design for automation equipment

Machine Design Engineered to Perform

Automation machine design is exclusively a 3D process at Cardinal Machine Company. All mechanical designs have been exclusively created in 3D since 1997. SOLIDWORKS® is our primary CAD software for mechanical engineering and surface modeling, and latest software versions are always utilized. When called for we can perform finite element analysis (FEA), including fatigue analysis. SOLIDWORKS® Simulation is used for all FEA studies.

SOLIDWORKS

SOLIDWORKS is used to develop mechatronics systems from beginning to end. At the initial stage, the software is used for planning, visual ideation, modeling, feasibility assessment, prototyping, and project management. The 3D modeling software is then used for design and building of mechanical, electrical, and software elements.

AutoCAD

AutoCad® is our primary design tool for controls engineering (electrical, fluid power) and the latest software versions are always utilized. We use the AutoCad® Electrical Toolset for the creation of controls drawings. The use of AutoCad® Electrical Toolset improves efficiency, reduces errors, and essentially creates a smart design package

The Best Tools, The Best People, The Best Processes

How We Achieve World-Class Automation Equipment Machine Design

At Cardinal Machine Company, we use the latest equipment, adhere to the highest standards, and employ the best machine builders on the planet to deliver cutting-edge solutions that exceed our client's expectations.

Mechanical Design

All machine designs are generated using 3D modeling. Our computer-aided design engineering drawings and related documentation can be delivered in a variety of electronic and printed formats. Our electrical and fluid power designs are generated in the latest AutoCAD release.Design Software

We support a wide range of programming software, including, but not limited to, renowned platforms such as Allen Bradley, Modicon, Siemens, Mitsubishi, and GE Fanuc. Our mastery of these tools ensures the seamless integration of innovative features into our machine designs.

Facilities

Housed within our modern facility, spanning over 25,000+ square feet, we have the internal capabilities to take your automation machine design from concept to delivery. Our facility adheres to strict cleanliness standards, providing an ideal environment for the creation of exceptional automation solutions.

IT capabilities

We feature modern workstations and laptops supported by a multi-tiered server system, including continuous automatic data backup. Our constant investment in IT infrastructure serves as a vital conduit for fast and secure data transfer, enabling us to streamline processes, enhance productivity, and maintain a competitive edge in today's fast-paced digital landscape.

Process Development

Leveraging our equipment and engineering experience, we excel at overcoming various manufacturing process challenges in automation machine design. Our expertise spans a wide array of processes, including but not limited to MIG welding, TIG welding, plasma welding, resistance welding, laser welding, and high-pressure gas fill.

DESIGN FOR MANUFACTURABILITY (DFM)

Factors We Consider When Designing & Engineering Automation Equipment

.webp)

To achieve success in custom automation machine design and engineering, Cardinal abides by a proven, reliable process, one that considers all aspects of a machine’s requirements, including product needs as well as business needs.

Our goal is to create a product that is successful for years to come, enabling worry-free productivity and long-term profitability. To achieve this, we adhere to the standards of Design for Manufacturability (DFM) throughout our entire product development process.

Incorporating DFM standards into our machine design philosophy is a crucial aspect of our approach. It ensures that our machines not only embody innovation and functionality but are also designed with practicality in mind, enabling smooth and efficient production processes.

Here are the principles we take into consideration when designing a machine or system.

- Business and Product Planning and Goals

- KPIs and Operational Metrics

- Understanding Added Value Product Costs at Each Stage

- System Flexibility

- Contingency Planning for Disruptions or Failures

- Automating the Machine Design as Much as Possible

- Performance Reporting and Feedback

- Serviceability

- And more...

What Our Machine Design Clients Say

Edmond S.

Joyson

Gasfill scrap ran .46% of total production last month which is very good.

Mark A.

Delphi

Thanks again for sending them, and I look forward to future jobs with Cardinal Machine Company.

We Look Out for You

Why Choose Cardinal for Machine Design?

Our suite of machine engineering services are unrivaled. We cover all the bases.

Experienced Technical Team

We cover all the bases of custom machine making, from engineering to design to building to testing and commissioning.

Global Sales & Installation

We are North American based, but we can and will go anywhere to help manufacturers with their custom machine needs.

Cost-Effective Designs

Affordability is always top of mind. We are cognizant of the pricing pressures placed on manufacturers in today's global economy.

Lean Organization

At Cardinal, we adhere to Lean Manufacturing principles so as to create the most productive, most efficient environment possible.

Dedicated Project Managers

Each Cardinal client gets a dedicated project manager who stays with their project for the full duration of its lifecycle. And beyond.

A Dedicated Team

Our technical team has been providing specialized machine building services since 1972. We bring continuity, integrity and real-world experience to everything we do.